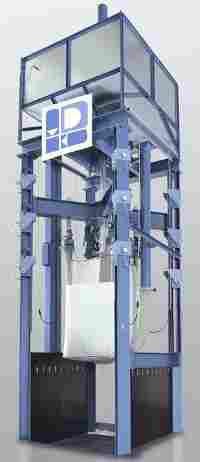

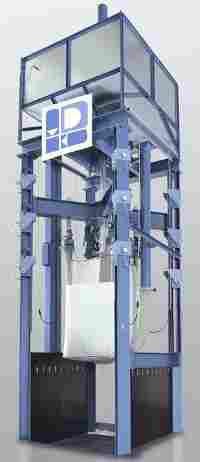

FIBC Test device UVP 300

The first generation of this famous test rig has been developed in the early seventies. It was the first one world-wide. Now we offer the third generation of this device based on the experiences and requirements of an immense number of tests done within more than twenty five years. The test rig has been sold to many FIBC-manufacturers in Europe and overseas where it has become the most important tool for quality controlling and product developing.

The device is adequate to that one which LABORDATA INTERNATIONAL MATERIALS TESTING INSTITUTE is actually using.

|

Top Lift Tests and Cyclic Top Lift Tests of FIBCs with single-point and multi-point suspension according to all National and International Standards can be performed in an easy, quick and accurate manner on a high technical standard.

The device is available in three versions:

- Version A (with excavation below the floor)

- Version B (if a cellar exists below the floor)

- Version C (with platform above the floor)

If possible you should prefer version A (or B) because version C has many disadvantages in use.

The equipment includes:

- Steel construction of high stability painted with colour of your choice

- Receiver for the granulate in the base of the machine

- Elevator for direct transport of the granulate from the receiver into the test piece (average filling time 10 minutes per cubicmetre)

- Hydraulic cylinder (max. stroke 2,5 m) and hydraulic pump with control valves (max. test load 200 kN)

- Automatic turn off in the final positions of the hydraulic cylinder

- Control centre for the electronic measuring devices with all operating switches

- Additional remote control at the test rig for operating during installation of the test piece.

- Four load cells (each 50 kN)

- Digital displays for the current load and memory for the breaking load

- Automatic running of cyclic loadings

- Set of load plates for different sizes of FIBCs

- Three positions of the load cross adaptable to different heights of FIBCs

- Computer with interface and printer

- Software for recording complete test reports inclusive diagrams

- Software and Standard Measure for load cell calibration

- In order to accelerate the filling of the test pieces a 3 m³-silo for the granulate can be installed at the top of the test rig. Filling of the test piece will be done from the silo (average filling time one minute per cubicmetre); inclusive a remote controlled slider and automatic elevator stop set off by filled up silo.

|

|

(054)