|

Dr. Herbert Kielbassa, managing director of the world renowned LABORDATA International Materials Testing Institute, has an unrivalled knowledge of the global FIBC industry. |

Controlling FIBC quality - theory and practice

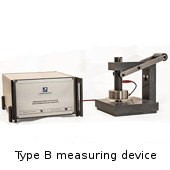

| An industrial product can only survive if its quality is up to standard. This required standard is determined by two separate camps with distinctly different priorities but ultimately the same objective. On the one hand there are those who draw up and enforce regulations, standards and statutory laws; on the other hand the interests of the market concerning manufacture, design, quality, delivery performance and price need to be met. This polarity converges with the ISO 9000 standards. These standards started well as a sound basis for cooperation between producers and customers. After all the aim of the ISO 9000 standards is to create a basis for mutual trust in a product of constant quality. That is the theory. But what is really happening in the FIBC sector? Most FIBC manufacturers are certified to ISO 9002, though some prefer ISO 9001. They are brandishing their ISO certificates like a demonstration placard in order to show to their customers that their products attain a high standard of quality. Of course they have every right to do so and by flourishing this placard they demonstrate their pride. But is an ISO certificate a real proof or guarantee of quality? No, very far from it. Quality cannot be ensured just by having devised a quality assurance manual which goes into every detail. The quality assurance plan must be implemented in every detail as well. This presupposes a quality assurance management which organises constant documentation of all details, supervising that they are adhered to and eliminating any weck points. Apart from comprehensive documentation of factors relating to quality, | it is necessary to have access to all relevant test and laboratory equipment as well as to qualified personnel. The staff involved in the quality assurance, management as well as laboratory technicians, must have a sufficient level of knowledge and information about regulations and standards appertaining to FIBC matters. Here, serious gaps can often be found especially with regard to UN regulations. According to a rough estimate, only one third of all FIBC manufacturers fulfil all the requirements and are able to justify the announced ISO quality standard. Another third have difficulties in keeping to the terms of the ISO certification but somehow manage to cheat their way through from audit to audit. The final third fail to attain any of the preconditions which might qualify them for a basic ISO certificate. Yet sometimes it happens that companies in this last category manage to obtain ISO certification. This can occur in the event that auditors are overstretched or that certification has been gained by some other dubious manner. For example: how is it possible that ISO certification can be issued to companies that neither have an FIBC test rig, nor are able to prove that they carry out the necessary tests regularly through an external test house? For a proper quality assurance it is not sufficient just to check the mechanical properties of the material components (fabrics, webbing, yarns, etc) which are intended to be used for manufacturing FIBCs. Without testing samples of the finished product according to a checklist established by the quality management using top lift tests and (especially in the case of UN bags) drop tests and topple tests, a quality guarantee is impossible. | But many manufacturers do not own such test devices and not all the devices which are in use meet the requirements for correct test procedures. The lists of faults regarding these tests discovered through third party inspections are not amusing and in the case of ISO certified companies they are very annoying. Even dark practices do occur as revealed in the following example. An inspection agency (see certificate (190kB)) certifies that an FIBC manufacturer has all the necessary items of equipment at his disposal which are required to perform quality control tests according to UN regulations and that this has been verified by successful tests witnessed by a representative who attended the tests. You can read: "Our Representative attended the testing laboratory of ..... in order to witness the following tests:

TEST RESULTS: At the end of the a/m tests on the submitted FIBC samples, they were found to be in compliance with the UN (United Nations) Recommendations on the Transport of Dangerous Goods Chapter 6/Tenth Edition." Unfortunately the highly acclaimed company has none of the devices mentioned in the certificate and was unable to perform the tests in any manner. There were no tests which could be attended by the representative of the agency. This certificate is perfidious and irresponsible, even more so because dangerous goods are involved and the company's deceit is in complete disregard for human health and the environment |

Comments are welcome and these may be sent by letter to Dr Kielbassa, c/o INDUSTRIAL BULK WORLD, 25 West Cottages, Off West End Lane, London NW6 1RJ, UK. Alternatively, he can be contacted direct (tel: +49 531 33 9011, fax: +49 531 33 9013; email: This email address is being protected from spambots. You need JavaScript enabled to view it.).

(53)